Additive manufacturing (AM), also popularly known as 3D printing, is a manufacturing technology that has been evolving since the late 1980s—but can finally be said to be proving its worth in many fields. It is a layer-by-layer process by which material, metal, plastic, alloy, or a combination is fused or bonded to produce the desired part.

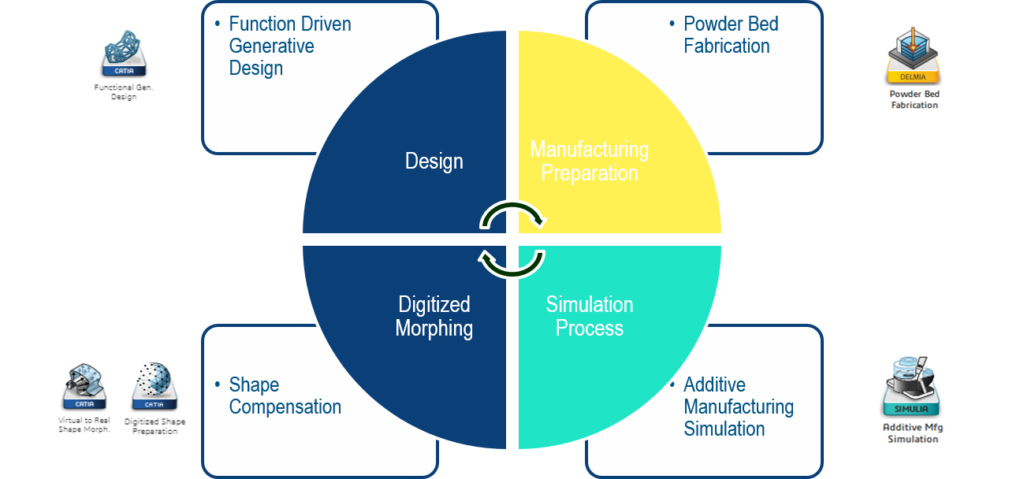

There are a number of key areas where simulation can play an important role in 3D printing: generating a functional design, generating lattice structures, calibrating the material, optimizing the manufacturing process, and in-service performance.

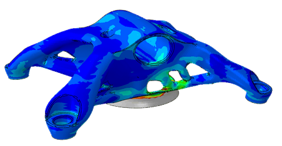

AM is unique in offering designers freedom from traditional manufacturing constraints, allowing them to take their designs to new heights to meet engineering requirements without sacrificing part strength or performance. Lightweighting is an example of this: parts can be created with a minimum of material necessary to meet specified functional requirements. Creating these kinds of designs is now feasible thanks to the proven technology of robust, nonlinear topology optimization that SIMULIA offers through the Tosca suite of products.

Solution Overview and Workflow

Generative Designer

Function Driven Generative Designer (GDE)

GDE allows the designer to capture all functional specifications: geometrical inputs, analysis inputs, optimisation targets and constraints. Seamless Collaboration with Designers, Simulation and Manufacturing Engineers.

Engineer

Additive Manufacturing Engineer (AMR)

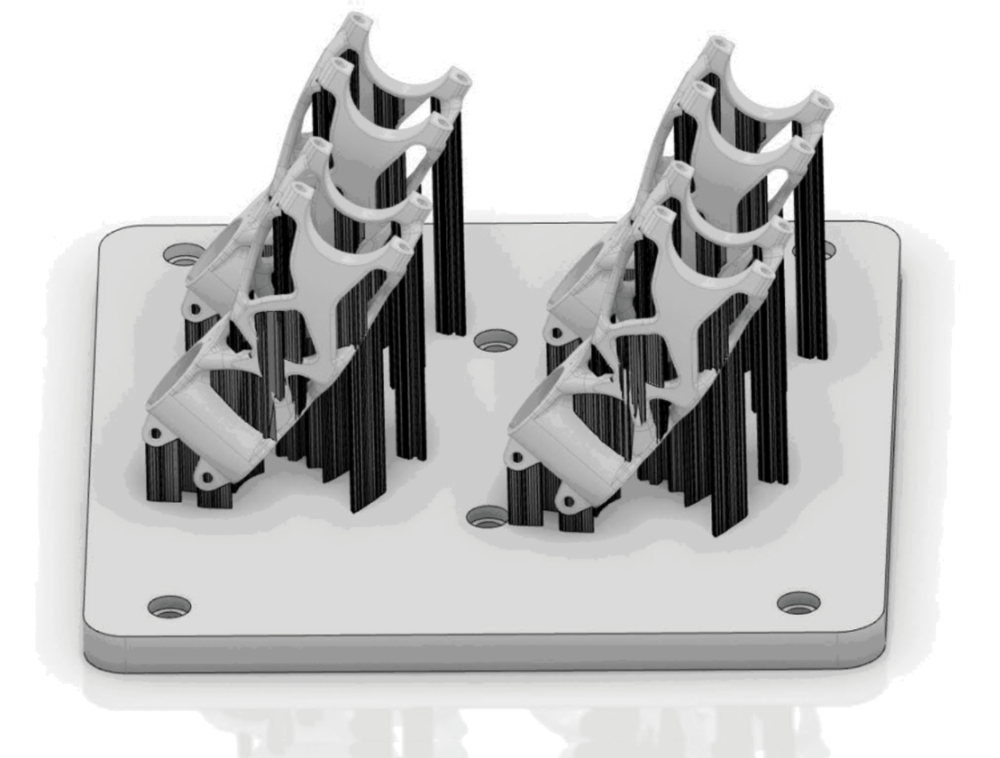

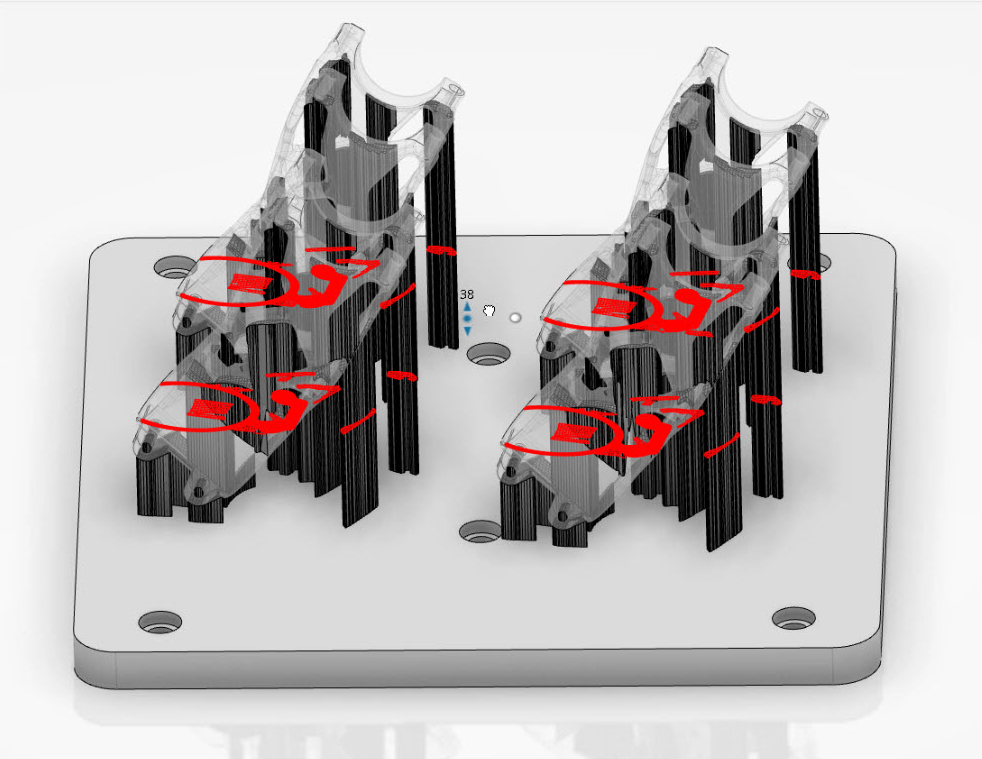

AMR allows users to apply appropriate strategies and control quality variables for both parts and supports. This helps improve quality of the part and also mitigate waste during production. AMR also generates outputs to be sent tot he industrial 3D printer.

Machine Programmer

Additive Manufacturing Programmer (AMP)

AMP has a unique capability to generate scanned paths based on the 3D geometry. This helps improve quality of the part and also mitigate waste during production. The laser path can then be output in 3MF, AMF and STL formats.

Simulation Specialist

Additive Manufacturing Researcher (MDA)

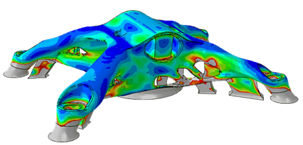

MDA allows the user to conduct a physically realistic process-based simulation of a part to be manufactured by 3D printing. The SIMULIA Additive Manufacturing Scenario app leverages information using the DELMIA Powderbed Fabrication app during the simulation. It offers a high level of automation and guidance to allow the user to easily setup complex simulations. It allows for increased dimensional accuracy, and eliminates unnecessary and costly physical test prints.